Garments Costing for Knitted Polo Shirt

Introduction:

In garments merchandising, costing is a very important issue. As its importance in

garments sector, today its seen that, some buying house make an another

department only for costing. The main reason of that is to prepare accurate

costing for any order. To make accurate costing you have to know the method of

costing, by which you can solve any costing issue without any hesitation.

Method of Garments Costing for

Knitted Polo Shirt:

Before starting of a knitted polo shirt garments costing,

a knit garments merchandiser must be known about the following matters:

1.

Yarn Price,

2.

Knitting and Washing

Cost,

3.

Dyeing Cost,

4.

Embroidery Cost,

5.

Printing cost,

6.

Accessories Cost,

7.

Cost of Making (CM),

8.

Commercial Cost,

9.

Others Cost.

Important tips***

§ The 2nd duty is to calculate the fabric

consumption and costing.

§ Normally, we calculate the grey fabric

consumption.

§ After completing grey fabric consumption and

costing, all the required fabric processing cost (knitting+ washing cost,

dyeing cost) should be added with grey fabric cost. After that, we can achieve

the actual fabric cost.

§ At last, all the others necessary cost should

be added with actual fabric cost to achieve total cost of a garment.

An example for the knitted polo shirt garments

costing method are presented in the below:

Example:

Suppose,

One of the buyers named “Ha-Meem Group” forwards a knitted polo shirt item

order (20000pcs) to you with following specification.

1. 100% cotton single jersey fabric for body

parts (Body + Sleeve), Half-moon and Pocket. Where fabric GSM is 170.

2. 1 × 1 Rib fabric for collar and Cuff. Where

the fabric GSM is 220.

Follow the below measurement chart.

3. Print on Pocket.

4. Embroidery on Back part.

Follow the below measurement

sheet.

|

Actual length |

Allowance |

Measurement with Allowance |

|

|

Body length |

65cm |

6cm |

71cm |

|

Sleeve length |

18cm |

6cm |

24cm |

|

½ Chest width |

50cm |

6cm |

56cm |

|

Collar length |

36cm |

0cm |

36cm |

|

Collar width |

7cm |

3cm |

10cm |

|

Cuff length |

20cm |

4cm |

24cm |

|

Cuff width |

3cm |

2cm |

5cm |

|

Pocket length |

11cm |

3cm |

15cm |

|

Pocket width |

8cm |

3cm |

11cm |

|

Half-moon length |

14cm |

3cm |

17cm |

|

Half-moon width |

7cm |

3cm |

10cm |

Now, determine the garments costing (On FOB)

for the above order.

Solution:

Fabric GSM- 170 for

cotton single jersey,

Fabric GSM- 220 for 1 × 1 Rib fabric.

Let,

Yarn Price per kg- $3.90

Knitting and Washing Cost per kg- $1.50

Dyeing Cost per kg- $2.10

Printing Cost per dozen- $3.90

Embroidery Cost per dozen- $6.00

Accessories Cost per dozen- $2.00

Now, we have to calculate the fabric

consumption for the above order.

Fabric Consumption:

1. Fabric consumption for Body parts (Body +Sleeve):

Here, we will follow the following formula (per dozen),

= 2.17kg per dozen.

So, fabric consumption

for Body parts (Body +Sleeve) is 2.17kg per dozen.

2. Fabric consumption for Collar:

Here, we will follow the following formula (per dozen),

= 0.10kg per dozen.

So, fabric consumption for Collar is 0.10kg per dozen.

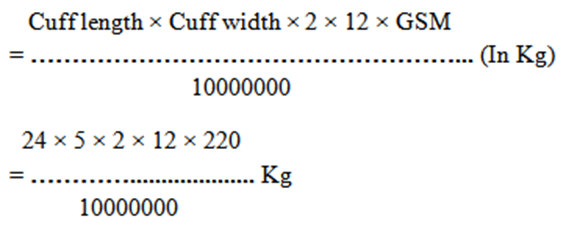

3. Fabric consumption for Cuff:

Here, we will follow the following formula (per dozen),

So, fabric consumption

for Cuff is 0.06kg per dozen.

4. Fabric consumption for Pocket:

Here, we will follow the following formula (per dozen),

So, fabric consumption for Pocket is 0.03kg per dozen.

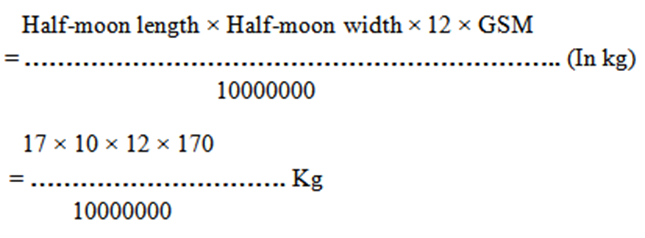

5. Fabric consumption for Half- moon:

Here, we will follow the following formula (per dozen),

= 0.03kg per dozen.

So, fabric consumption for Half- moon is 0.035kg per dozen.

Now, total amount of cotton single jersey fabric needed for this

order is (per dozen),

= [{Fabric consumption for Body parts (Body +Sleeve) + Fabric consumption for

Pocket + Fabric consumption for Half- moon} + wastage (10%)]

= {(2.17 + 0.03 + 0.03) kg + 10%}

= 2.23kg + 10%

= 2.45kg per dozen.

So, cotton single

jersey Grey fabrics needed per dozen 2.45kg.

And,

Total amount of (1 × 1) Rib fabric needed for this order is (per

dozen),

= {(Fabric consumption for Collar + Fabric consumption for Cuff) + wastage

(10%)}

= {(0.10 + 0.06) kg + 10%}

= (0.16kg + 10%)

= 0.18kg per dozen.

So, 1 × 1 Rib Grey

fabrics needed per dozen 0.18kg.

Total grey fabric

needed to make the polo shirt is – (2.45+ 0.18 = 2.63kg) per dozen

As yarn price per kg is $3.90 then, total grey fabrics cost per dozen is

(2.63kg × $3.90) = $10.26

So, Total grey fabrics cost per dozen is $10.26

Now, adding all the fabric processing cost (Knitting+ Washing Cost, Dyeing

Cost) with grey fabrics cost, actual fabric cost will be determined.

So,

Actual fabric cost,

= Total Grey fabric cost + [{(knitting cost + washing cost) + dyeing cost} ×

Total grey fabric] per dozen

= [$10.26 + {($1.50 + $2.10) × 2.63}] per dozen

= $19.79 per dozen.

So, actual fabric cost

per dozen is………. $19.73 ………………….. (A)

Printing Cost per dozen……………………… $3.90 ………………………. (B)

Embroidery cost per dozen ………………… $6.00 ……………………….. (C)

Accessories Cost per dozen……………….…$ 2.00 ………………………… (D)

Cost of making (CM)……………………………. $5.00 ………………………… (E)

Commercial cost …………………………………. $0.55 …………………………. (F)

Others cost …………………………………………. $0.25 ………………………… (G)

Here,

By adding A, B, C, D, E, F and G, we will get the total FOB cost of garments

per dozen for the above order.

Total FOB cost per dozen = (A +B + C + D+ E + F + G)

= $ (19.73 + 3.90 + 6.00 + 2.00 + 5.00 + 0.55 + 0.25)

= $37.43 per dozen.

So, total FOB cost per

dozen is $37.43

Normally, in case of

factor costing, it should be think that, as we have received the order from a

buying house (Here, we got the order from Ha-meem Group’s Buying House), so we

have to pay 8%commission to them for that order.

So, in this condition, total FOB cost per dozen stands at-

= $37.43 per dozen + 8% commission

= $40.42 per dozen.

In factory costing,

profit% for the factory (here-10%) should be added with total FOB cost per

dozen.

So,

Total FOB cost per dozen with profit% stands at ($40.42 + 10%) = $44.46

Now, total FOB cost

per pcs is ($44.46 / 12) = $3.71

So, factory cost (FOB)

per pcs garment of the above order is $3.71

No comments:

Post a Comment